Parotec are market leaders in designing and manufacturing protective foam with over 20 years of experience.

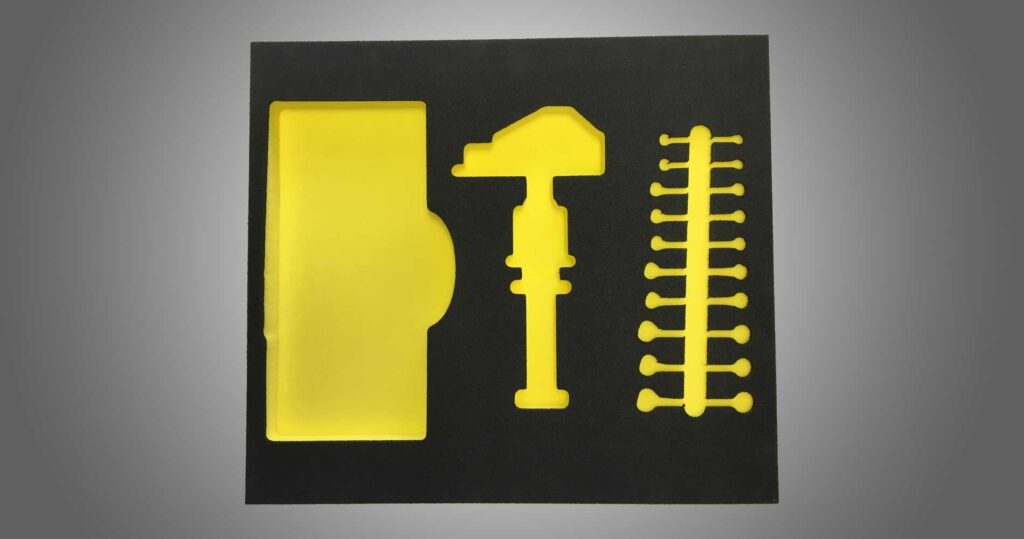

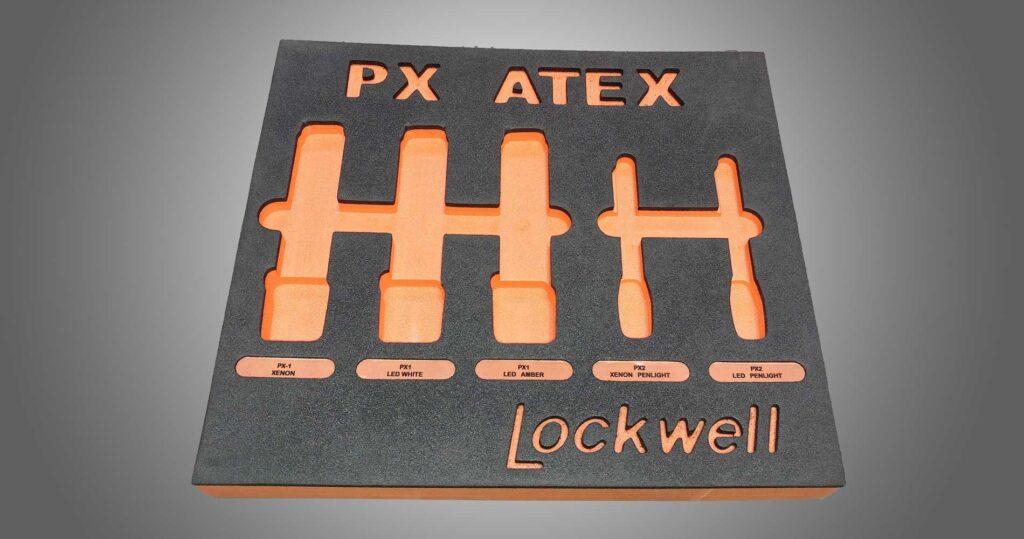

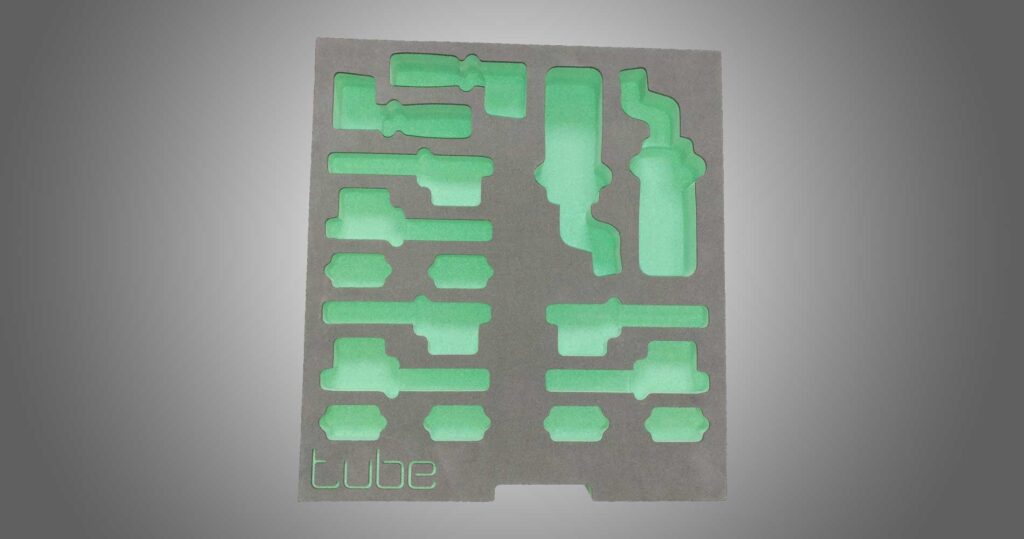

Our facilities can cut various grades of foam to accommodate the most complex of product shapes. Alongside our CAD abilities we can design and customise protective foam for all use cases.

Speak to one of our experts today

What foam cutting services are there?

We offer a range of foam cutting services to create custom foam inserts through our bespoke Foam Design System and laser cutting services.

First and foremost we are custom foam manufacturers but we offer much more besides.

Our specific foam engineering services include:

CNC Routing

Our modern CNC routing machinery cuts various grades of foam. Capable of cutting the most complex of product shapes, the CNC machinery can deliver precision and repeatability, as well as impressive speed of production and cost effectiveness.

A variety of foam types are used depending on the size and weight of the items it will contain. Utilising the latest CNC technology, our large machines enable us to route multiple units.

Also, due to the elimination of tooling costs, the process can create one-off routed foam inserts just as effectively.

Die Cutting

For larger volume orders, the process of die cutting allows foam to be cut quickly and efficiently by removing or shearing material. Each design would require a new tool to be used.

Water Jet

Water jet cutting can be used to cut a variety of materials by use of extremely high pressure water jets. Depending on the material needing to be cut or accuracy needed in the cutting process, Parotec are able to offer this as a service to our customers

Foam Design System

The Parotec Foam Design System (FDS) uses cutting edge technology to allow foam inserts to be designed and configured using an online graphical editor.

By using this technology, we are able to supply our customers with images of how their finished foam will look, along with an accurate quote.

Once this design has been created, it is permanently saved which allows further orders or edits to be quickly completed.

What types of foam are there?

We work with a range of different foam, including:

Expanded Polyethylene

Expanded Polyethylene is a lightweight, closed-cell foam most commonly used in packaging.

It’s used for impact and shock absorption, vibration dampening and surface protection. It is easily shaped, formed and cut to size. EPE is dust-free and non abrasive.

Key Features:

- High buoyancy

- Excellent heat insulator

- Durable and high resilience

- Shock absorbing

- Mildew, bacteria and rot resistant

- Resistant to wear and tear

Expanded Polyurethane

Expanded Polyurethane is a softer, open-cell type of foam that is made in varying degrees of firmness.

Because the cells are open and not cross-linked, air can flow throughout the foam just like water can flow throughout a sponge.

Expanded Polyurethane can provide more cost-effective, form-fitting cushioning that uniquely and securely protects items that need to stay safely in place during transit.

Key Features:

- Shock absorbency

- Dampens vibrations

- Lightweight for buoyancy uses

- Cushioned support

- Flexible

- Non-abrasive

- Tear resistance

We always have a wide range of foam types and colours available to us off the shelf – we can also source specialised types of foam if required, giving you a huge choice.

Most applications will require Expanded Polyethylene foam, which is available to us in a wide range of vivid, attractive colours in addition to standard Black.

Please contact us to find out more about what we can offer you and how we can meet your requirements.